|

Drill Grinding

Procedures: Web Thinning

|

| Web

Thinning

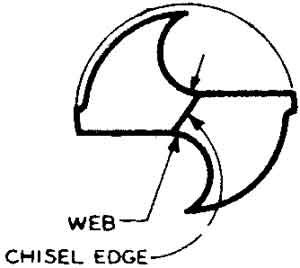

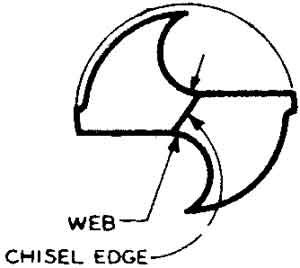

On a conventional twist drill bit there is what is known as a web. The

web is the center part of the body that joins the lands (Figure 1). |

Figure 1 Twist drill point

|

| The extreme ends of the web form the chisel edge. The

thickness of the web is not uniform; it increases from the point to the

shank (Figure 2).

Figure 2

The web thickness gets larger

toward the shank of the drill.

|

|

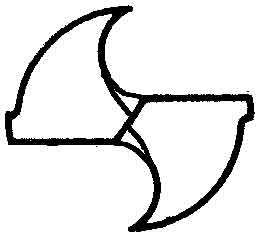

The cutting action of the chisel edge requires a relatively large amount of

thrust be used to cause the drill to penetrate into the workpiece. The increased

amount of thrust needed to drive the chisel edge becomes more apparent as the

drill is sharpened, since the web of the drill is made thicker toward the shank.

We can reduce the amount of force it takes to cause the drill to penetrate by

thinning the web of the drill (Figure 3).

|

|

|

Figure 3 Web thinning |

The best way to thin the web of a drill is by using a machine equipped with a

drill point thinner. It is possible, however, to thin the web of a drill by hand

using a pedestal grinder.

| Web

Thinning on a Pedestal Grinder

When thinning the web be careful not to make the web any thinner than

it was when original and do not disturb the cutting lips of the

drill. Start with a clean, sharp grinding wheel. Hold the drill at

approximately 35 degrees of the axial centerline of the drill (Figure 4). |

Figure 4 Holding the drill at a 30- degree

angle

|

|

Figure 5 Line up the end of the web with

the corner of the wheel.

|

Line up the corner of the wheel with the tip of the web

(Figure 5).

Turn the cutting lip out approximately 10 degrees. Lightly grind away

the web of the drill. You have to grind the same amount off of each web to

assure that the drill point will remain on center. Try to stay away from

the cutting edge as much as possible.

|

Modified

split point done on a pedestal grinder

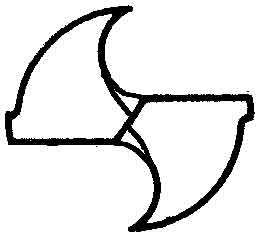

| It is sometimes easier for a beginning student to grind a

modified split point by hand than it is to do off-hand web thinning. The

split point drill (Figure 6) accomplishes the same end result, a thinned

web, but you are actually grinding away the heel or non-cutting side of

the drill point. |

Figure 6 Split point

|

|

Figure 7 The approach angle is steeper

when web splitting than it is when web thinning.

|

Start with a clean, sharp grinding wheel. Hold the drill at

approximately 55 degrees off of the axial centerline of the drill (Figure 7). |

| Line up the corner of the wheel with the tip of the web

(Figure 8). Turn the cutting lip out approximately 10 degrees away from

the wheel edge.

Lightly grind away the heel of the drill until you have ground away the

appropriate amount of the web of the drill. |

Figure 8 Line up the end of the

web with the corner of the wheel.

|

|