|

Cutting Fluid Types and Uses

|

Cutting fluids are very important in machining processes. They are used to

reduce the effects of friction. They are also used to carry away heat in

machining operations. Excessive heat can damage the microstructure of metals.

Proper use of coolants can make higher metal removal rates possible. Coolants can

also help improve part quality and dimensional accuracy.

The student will be able to:

- Explain the importance of cutting fluids in machining.

- Explain the common types of coolants available.

- Select the proper coolant for various machining operations.

There is a wide variety of cutting fluids available today. Many new coolants

have been developed to meet the needs of new materials, new cutting tools, and

new coatings on cutting tools. The goal of machining operations must be to

improve productivity and reduce costs. This is accomplished by machining at the

highest practical speed while maintaining practical tool life, reducing scrap,

and producing parts with the desired surface quality. Proper selection and use

of cutting fluids can help achieve all of these goals.

In machining almost all of the energy expended in cutting is transformed into

heat. The deformation of the metal to create chips and the friction of the chip

sliding across the cutting tool produce heat. The primary function of cutting

fluids is to cool the tool, work piece, and chip, reduce friction at the sliding

contacts, and prevent or reduce the welding or adhesion on the contact

edges that causes a built-up edge on the cutting tool or insert. Cutting fluids

also help prevent rust and corrosion and flush chips away.

Most shops try to reduce the number of different types of fluids that they

keep in stock. They try to stock fluids that have long-life, do not need to be

changed constantly, donít smoke in use, and donít cause skin irritation. One

large consideration is disposal. It is very costly to

dispose of cutting fluids.

Cutting Fluid Purposes

|

Cooling

Machining operations create heat. This heat must be removed from the process.

The chip helps carry away heat from the tool and work piece. Coolant takes heat

from the chips tool, and work piece. To be effective the fluid must be able to

transfer heat very rapidly. The fluid absorbs the heat and carries it away.

Lubrication

In a typical machining operation, two-thirds of the heat is created by the

resistance of the work piece atoms to being sheared. The friction of the chip

sliding over the cutting tool face creates the other one-third of the heat.

Cutting fluid with good lubrication qualities can reduce the friction of the

chip sliding over the tool face. The lubrication actually changes the shear

angle, which reduces the shear path and produces a thinner chip. Good

lubrication also reduces internal friction and heat through less molecular

disturbance.

Benefits - Effective use of coolants

| Improve Part Quality |

The use of cutting fluids reduces friction and heat. The removal of the

heat prevents the work piece from expanding during the machining

operation, which would cause size variation as well as damage to the

materialís microstructure. |

| Reduce tooling costs |

Proper use of cutting fluids increases tool life, which reduces the

tooling costs. Increased tool life also reduces tool changes and downtime

which decreases labor costs. |

| Increase Cutting Speeds and Feeds |

Cutting tools reduce friction and heating a machining operation. This

allows high speeds and feeds to be used to achieve optimal cutting

conditions. |

| Improved Surface Finishes |

Effective use of cutting fluids helps remove the chips. This prevents

the chip from being caught between the tool and work piece where it causes

scratches and a poor surface finish |

| Reduces Bacterial Growth |

Bacteria can drastically affect cutting oils. Bacteria growth can turn a

cutting fluid rancid. Additives in coolants help reduce the effects of

bacteria, but it is important that pure water is used for coolant mixing. |

| Rust and Corrosion Prevention |

Cutting fluids should protect the tooling, machine, and work piece

against rust and corrosion. Cutting fluids should leave a small residual

film that remains after the water has evaporated. |

Cutting fluids can be broken into four main categories: straight cutting

oils, water miscible fluids, gasses, and paste or solid lubricants. Two of the three

(chemical-based and emulsions) are primarily water. Water quality has a large

effect on the coolant. Water that is very hard (high mineral content) can cause

rust, stains, and corrosion of machines and work pieces. Water can be deionized

to remove the impurities and minerals.

Water is the best fluid for cooling. It has the best ability to carry heat

away. Water, however, is a very poor lubricant and causes rust.

Oil is great for lubrication but very poor for cooling. Oil is also

flammable.

You can see that water and oil have some great strengths but also some

great weaknesses. If water and oil are combined, we get the best of both and

minimize the weaknesses. Water-soluble fluids have been developed that have good

lubrication, cooling ability and rust and corrosion resistance. These fluids

are usually mixed in the shop. It is crucial that the mixing directions and

concentrations are followed very closely to get the maximum benefit from the

coolant.

Water Miscible Cutting Fluids

|

Emulsions

Emulsion is a term that describes soluble oils. An emulsion is a suspension

of oil droplets in water. Soluble oils are mineral oils that contain

emulsifiers. Emulsifiers are soap-like materials that allow the oil to mix with

water. Emulsions (soluble oils) when mixed with water produce a milky white

coolant. Lean concentrations (more water-less oil) provide better cooling but

less lubrication. Rich concentrations (less water- more oil) have better

lubrication qualities but poorer cooling.

There are different types of soluble cutting fluids available including

extreme pressure soluble oils. These should be used for extreme machining

conditions where it is necessary to reduce friction where the tool and work

piece contact each other.

Chemical Fluids

Chemical coolants are also miscible cutting fluids. Chemical cutting fluids

are pre-concentrated emulsions that contain very little oil. Chemical fluids mix

very easily with water. The chemical components in the fluid are used to enhance

the lubrication, bacterial control, rust, and corrosion characteristics. There

are several types of chemical coolants available, including coolants for extreme

cutting conditions.

Inactive chemical cutting fluids are usually clear fluids with high rust

inhibition, high cooling, and low lubrication qualities. Active chemical fluids

include wetting agents. They have excellent rust inhibition and moderate

lubrication and cooling properties. Some contain sulfur or chlorine additives

for extreme pressure cutting applications.

Semi-chemical Coolants

Semi-chemical fluids are a combination of a chemical fluid and an emulsion.

They have a lower oil content but more emulsifier. This makes the oil droplets

much smaller. They have moderate lubrication and cooling and high rust

inhibition properties. Sulfur, chlorine, and phosphorous are sometimes added to

improve the extreme pressure characteristics.

Straight Cutting Oils

Straight cutting oils are not mixed with water. Cutting oils are generally

mixtures of mineral oil and animal, vegetable, or marine oils to improve the

wetting and lubricating properties. Sulfur, chlorine, and phosphorous compounds

are sometimes added to improve the lubrication qualities of the fluid for

extreme pressure applications. There are two main types of straight oils: active

and inactive.

Inactive Straight Cutting Oils

Inactive oils contain sulfur that is very firmly attached to the oil. Very

little sulfur is released in the machining process to react with the work piece.

Mineral oils are an example of straight oils. Mineral oils provides excellent

lubrication, but are not very good at heat dissipation (removing heat from the

cutting tool and work piece). Mineral oils are particularly suited to nonferrous

materials, such as aluminum, brass, and magnesium. Blends of mineral oils are

also used in grinding operations to produce high surface finishes on ferrous and

nonferrous materials.

Active Straight Cutting Oils

Active oils contain sulfur that is not firmly attached to the oil. The sulfur

is released during the machining operation to react with the work piece. These

oils have good lubrication and cooling properties. Special blends with higher

sulfur content are available for heavy duty machining operations. They are

recommended for tough low carbon and chrome-alloy steels. They are widely used

in thread cutting. They are also good for grinding as they help prevent the

grinding wheel from loading up. This increases the life of the grinding wheel.

Gasses

Cutting oils and water miscible types of cutting fluids are the most widely

used. Gasses are sometimes use. Compressed air and inert gasses are sometimes

used. Carbon dioxide, Freon, and nitrogen are also used

sometimes.

Paste and Solid Lubricants

Waxes, pastes, soaps, graphite, and molybdenum disulfide may be used. These are

generally applied directly to the work piece or tool, or in some cases,

impregnated directly into a tool, such as a grinding wheel. One example would

be lard. Many experienced journeymen recommend lard for tapping.

The Use of Cutting Fluids in Drill

Press Operations  |

The coolant should be aimed at the area where the tool contacts the work. It

should be flooded so that as much fluid as possible reaches the cutting edges.

The operator should withdraw the tool occasionally to remove the chips. The best

method is the use of tools that have integral oil holes. This means that various

tools are available that feed the coolant through the tool and directly to the

cutting edge (see Figure 1). This also helps wash the chips out of the hole.

Figure 1 Oil hole drills will supply cutting fluid

directly to the cutting edges of the drill.

| The Use of Cutting Fluids in Milling

Operations |

Two nozzles should be used whenever possible in milling operations. One

nozzle

should be in front of the cutter and one behind. Together they cool the tool and

the work piece and wash the chips away.

| The Use of Cutting Fluids in Turning

Operations |

In a turning operation, the coolant must be supplied to the area where the

chip is being produced. For turning and facing operations, the nozzle should be

directed so that the coolant is supplied directly over the tool. In heavy-duty

cutting, two nozzles would be advisable, one above and one below the tool (see

Figure 2).

Figure 2 For heavy cutting, it is advisable to have cutting fluid directed

at the top and bottom of the cutting area.

The Use of Cutting Fluids in Grinding

Operations  |

Grinding produces a great deal of heat because the wheel contains thousands

of small cutting edges, each producing heat as it cuts. Flood coolant is most

appropriate when grinding. When possible, use two nozzles for flood coolant, one

on the left and one on the right of the wheel. Keep the nozzles as close to the

work as possible. It is recommended that you use a dummy block on the side of

the workpiece. This helps get an adequate supply of coolant to the work at the

start of the cut.

|

Figure 3 No dummy block was used in

this case, so at the start of the cut there is very little coolant when

the cut begins.

|

Figure 4 In this figure a dummy

block was used. This assures adequate coolant at the start of the cut.

|

In cylindrical grinding, a fan-shaper nozzle that is slightly wider than the

wheel should be used. This assures that the entire grinding surface is flooded.

When internal grinding, the wheel should be as large as possible. The wheel

should be approximately 75% of the diameter of the hole in the workpiece. This

does not allow much room to get coolant into the bore. Make sure that an

adequate amount of coolant flows into the bore.

|

Material |

Milling |

Drilling |

Tapping |

Turning |

|

Aluminum |

Soluble oil (96% water) or mineral oil |

Soluble oil (70-90% water) |

25% sulfur-based oil mixed with mineral oil |

Mineral oil with 10% fat (or) soluble oil |

|

Brass |

Soluble oil (96% water) |

Soluble oil |

10-20% lard oil with mineral oil |

Mineral oil with 10% fat |

|

Bronze |

Soluble oil |

Soluble oil |

30% lard with mineral oil |

Soluble oil |

|

Alloy Steels |

10% lard oil with 90% mineral oil |

Soluble oil |

30% lard oil with 70% mineral oil |

25% sulfur base oil with 75% mineral oil |

|

Cast Iron |

Dry |

Dry |

Dry or 25% lard oil with 80% mineral oil |

Dry |

|

Malleable Iron |

Soluble oil |

Soluble oil |

Soluble oil |

Soluble oil |

|

Copper |

Soluble oil |

Soluble oil |

Soluble oil |

Soluble oil |

|

Low Carbon and Tool Steels |

Soluble oil |

Soluble oil |

25-40% lard oil with mineral oil |

25% lard oil with 75% mineral oil |

Coolant Maintenance

|

Maintain the coolant system correctly during and after mixing. Be sure to

allow for evaporation. To mix coolants, in a separate pail, add the desired

amount of water. Next add the desired amount of coolant. Pour the diluted mixture into

the machine sump. Remove floating tramp oils regularly. These oils cut off

oxygen from the coolant, and some may mix with the coolant, reducing its

effectiveness. Hydraulic fluids and other oils are major contributors to

rancidity. An oil skimmer will remove these oils efficiently, extending the sump

life. Keep the dirt levels low. This is particularly true in grinding

applications because high swarf promotes bacteria growth and leads to a poor

finish. Keep foreign matter out of the coolant in the sump. Cigarette butts and

similar trash will foul the coolant and clog the system. Try to aerate the coolant

when not in use so that the biocides can do their job. Test and evaluate coolants on

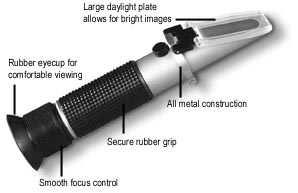

an ongoing basis. By using a refractometer (Figure 5), checking coolant dilution

levels is quick and easy. Refractometers are hand held, lightweight, portable

instruments used to determine the concentration of water soluble fluids, such as

machine tool coolants, heat treating fluids, hydraulic fluids, plating baths,

detergents, antifreeze, battery acid, and bodily fluids.

Figure 5 A refractometer is used to measure

coolant dilution.

Refractometers are very easy to use. Just place a few drops of fluid on the

prism and hold the unit up to a light source. Look into the eyepiece and read

the scale. To calibrate, just make sure the prism is clean and place a few drops

of tap water on the prism. The separation line should be on zero. If not, turn

the adjustment screw until it is.

Remember, refractometers read on a Brix scale not actual percent. To get the

actual percentage you must multiply the refractometer reading by your coolant's

refractive index (on product data sheet). With most soluble oils the index is 1,

so a Ref. reading of 5 x index of 1 = 5% concentration. However, many

semi-synthetics, synthetics, grinding fluids, and some soluble oils can have a

refractive index from 1.5 to 3. So a Ref. reading of 5 x index of 1.75 = 8.75%

concentration. This is most critical with solutions designed to be run at lower

concentrations, which have high indexes.

Always dispose of coolants properly. With all coolants, consult your

local, state or EPA regulatory office for guidelines.

Top

Top

|